Robust technology

Drum brakes are particularly robust and are well suited to heavy vehicles and high mileages. They work compactly and are less susceptible to crumbs or external contamination. A well-maintained drum brake ensures a consistent braking effect and durability even under demanding conditions.

Reliable braking power

In our store, you will find drum brake drums, adjustment mechanisms, brake shoe holders, spring washers and all the necessary accessories. These components can be used to replace worn parts without having to replace the entire brake – for cost-efficient repairs and sustainable maintenance.

The drum brake in commercial vehicle applications: robustness meets braking power

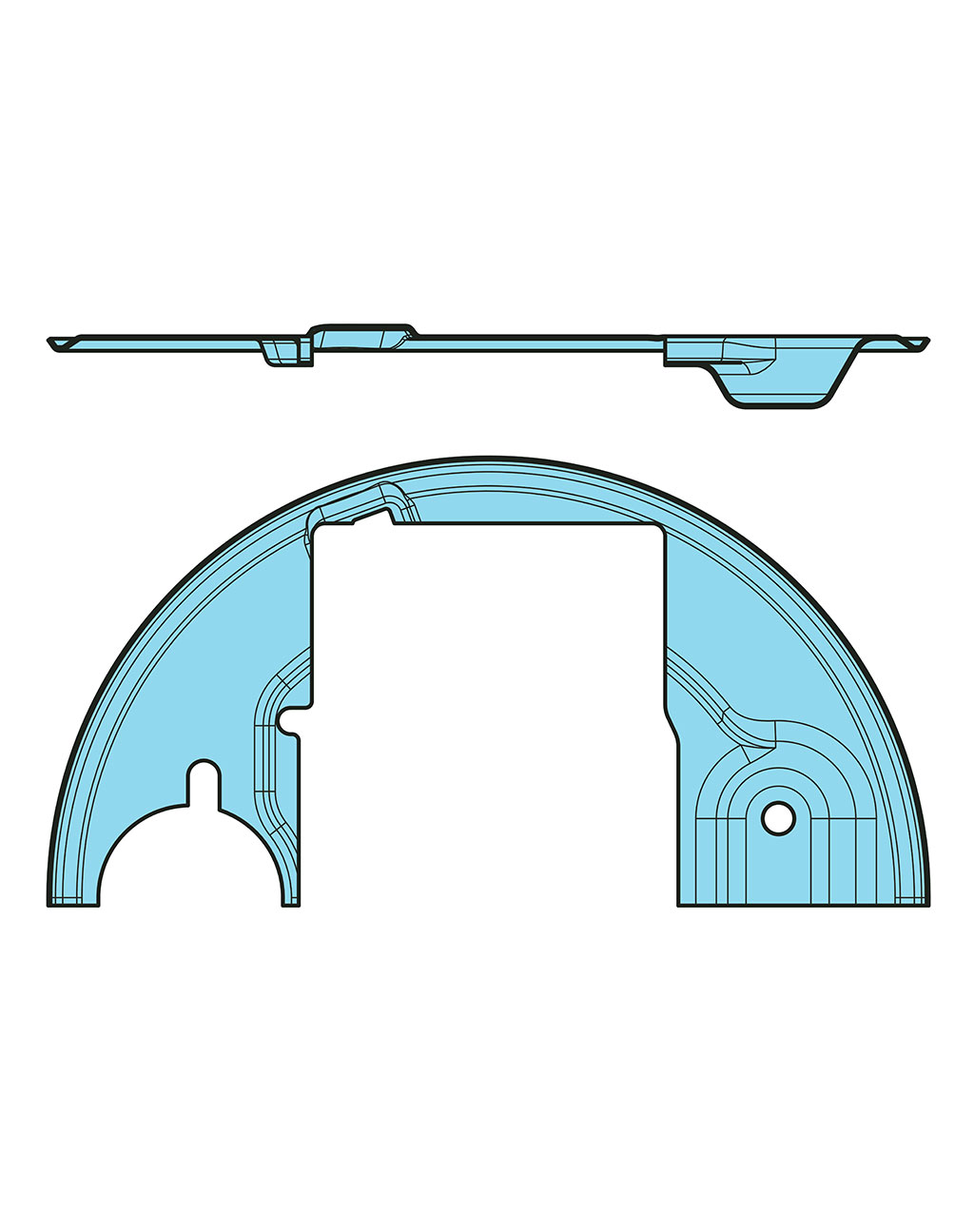

The drum brake is the epitome of reliability in the heavy-duty and off-road sector. This system scores particularly well on trucks, trailers and semi-trailers thanks to its enclosed design, which effectively protects the internal components such as brake shoes and wheel brake cylinders from dirt, dust and road salt. This design not only ensures constant braking performance under adverse conditions, but is also characterized by a high mechanical load capacity. The friction pairing between the lining and drum as well as the control by the brake linkage must be precisely matched so that the deceleration functions reliably even with a maximum load.

Ensure longevity with high-quality drum brake spare parts

Systematic servicing of the drum brake is the key to reducing the total cost of ownership (TCO) of your fleet. Wear on the brake drum or glazed brake linings not only impair the braking distance, but can also damage the wheel bearings due to excessive heat build-up. At FZB Fahrzeugbedarf, we consistently use spare parts in OEM quality. High-quality cast materials for the drums and non-toxic, durable linings guarantee an even wear pattern and optimum thermal dissipation. This prevents the dreaded brake fade on long downhill runs and ensures that your vehicles remain operational between the statutory inspection intervals.

Advantages of the design for heavy loads

The continuing popularity of the drum brake in the truck sector is based on two decisive advantages: Firstly, it offers the so-called self-energizing effect, in which the direction of rotation of the drum additionally presses the brake shoes into the drum. This maximizes the braking force with the same actuation force – an invaluable advantage in heavy-duty applications. Secondly, the drum brake is a closed unit. This provides optimum protection for the brake mechanism and linings against dirt, dust, water and road salt, which extends the maintenance intervals and ensures proper functioning under extreme conditions (e.g. on construction sites or in winter service).