Precision component for maximum motor performance

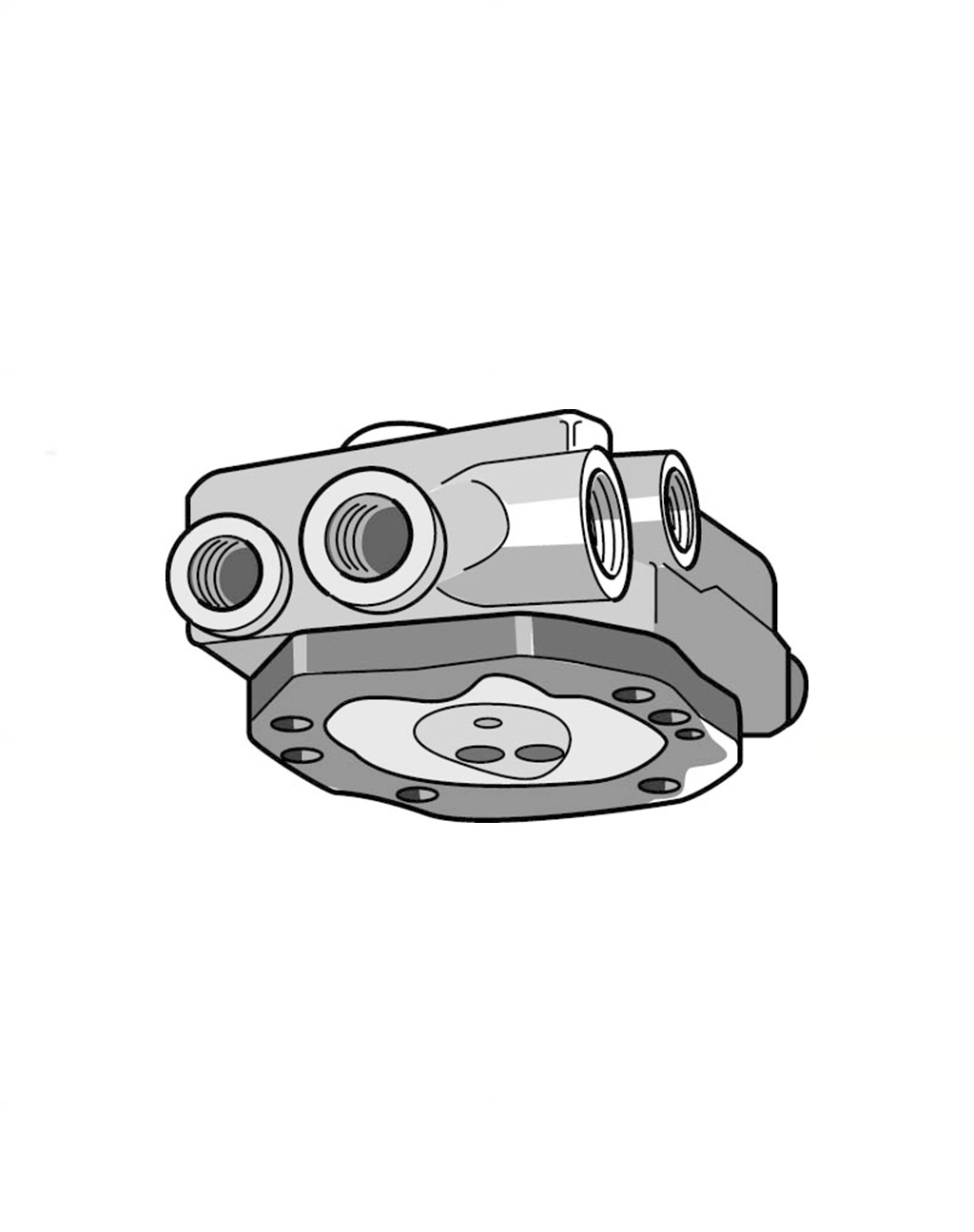

As the upper end of the combustion chamber, the cylinder head plays a central role in the efficiency and power delivery of your commercial vehicle engine. It not only houses the intake and exhaust valves, but also controls the entire charge exchange and ensures absolute sealing against high combustion pressures as well as coolant and oil circuits via the cylinder head gasket. In modern truck engines in particular, the cylinder head must be able to withstand extreme thermal stresses. Our spare parts guarantee the highest material quality and precise manufacturing tolerances to ensure optimum mixture formation and clean combustion in the long term.

Long service life thanks to cylinder head components in OEM quality

A defect in the cylinder head often leads to expensive downtime. Whether hairline cracks in the material, worn valve seat inserts or a leaking cylinder head gasket – repairs require components that are precisely matched to the engine manufacturer’s specifications. At FZB Fahrzeugbedarf, you will find complete cylinder heads as well as individual components and cylinder head bolts that are designed to withstand the enormous stresses of commercial use. Rely on tested quality to maximize the operational reliability of your fleet and effectively prevent costly consequential damage to pistons or crankshafts.

What should you look out for when buying:

Thermal and mechanical stress limits in truck diesel engines

The cylinder head in a truck diesel engine is the most heavily stressed component in the entire drive train. Due to the high compression ratios and the extreme peak pressures generated in modern turbo diesel engines (often to comply with Euro standards), the material of the cylinder head must withstand the highest thermal and mechanical limit loads. Heat dissipation is particularly critical: the head must effectively dissipate the heat from the combustion chamber via the coolant channels to prevent cracking or distortion. This requires a solid, precisely manufactured design, often made of special aluminum alloys or cast iron, which ensures durability in continuous operation.

Complex integration of injection and exhaust technology

In the truck sector, the cylinder head combines complex, high-precision components. It accommodates the injection nozzles, which work under extremely high pressure (up to $2,500\,\text$) in direct injection engines. The inlet and outlet ducts are specially adapted to the gas dynamics of the turbo engine to ensure optimum filling and emptying, which has a direct impact on performance and efficiency. In addition, the integrated components for exhaust gas recirculation (EGR ducts) and valve timing are of crucial importance. Any error in the manufacturing tolerance of the head or its sealing surfaces can disrupt the function of these systems and prevent compliance with the strict emissions regulations (e.g. Euro VI).

Maintenance reliability and spare part quality

Given the high costs and long downtimes associated with repairing cylinder head damage, the choice of spare part quality is a top priority in the truck fleet. When replacing the cylinder head or its components (valves, valve seats, head gaskets), care must be taken to ensure that the flatness of the sealing surface meets the manufacturer’s tight specifications in order to guarantee absolute tightness against the engine block. Only cylinder heads that meet these strict OE quality standards ensure the required mileage and prevent compression loss, oil loss and the mixing of cooling water and oil in tough continuous truck operation.