High-quality exhaust pipes for efficient emission control

A perfectly tuned exhaust system starts with the right exhaust pipe. In the heavy-duty use of trucks and commercial vehicles, these pipes have to withstand extreme temperatures of over 600°C and aggressive exhaust gases. Our exhaust pipes are made from high-strength aluminized steels or stainless steel to provide maximum corrosion resistance against road salt and moisture. A smooth internal flow also minimizes exhaust back pressure, which optimizes engine performance and sustainably reduces fuel consumption.

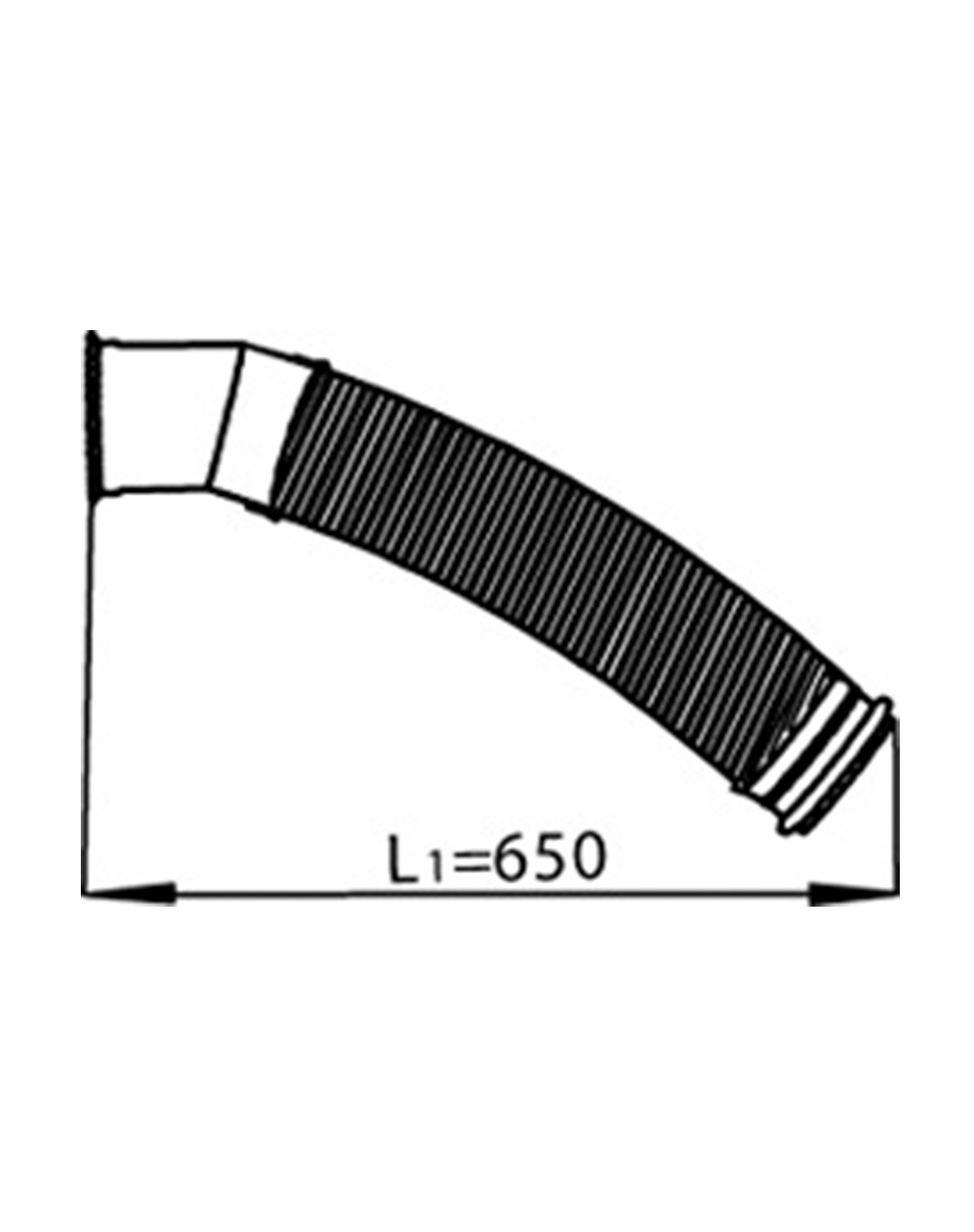

Flexible pipes and connecting pipes for long-lasting exhaust systems

Enormous dynamic forces act within the exhaust system. The connection between the engine and the permanently mounted silencer in particular requires flexible solutions. In addition to the classic exhaust pipe, FZB offers heavy-duty flexible pipes that reliably compensate for engine vibrations and thermal expansion. This prevents cracks from forming on expensive components such as the turbocharger or particulate filter. Rely on custom-fit connecting pipes and tailpipes in OEM quality to extend the maintenance intervals of your fleet.

What should you look out for when buying:

Thermal and mechanical extremes in the truck exhaust tract

The exhaust pipes of a truck are exposed to extreme conditions that far exceed what is usual in a passenger car. The massive diesel engines generate high exhaust gas temperatures, which reach peak values particularly in the vicinity of the turbos and exhaust gas aftertreatment (DPF/SCR). In addition, there are high mechanical loads due to permanent vibrations of the chassis and the engine as well as the torsion of the body. For this reason, truck exhaust pipes must have superior heat resistance and corrosion resistance (especially against aggressive condensates from combustion and AdBlue residues). Failure of a pipe can massively increase noise development and jeopardize the operating license.

Critical connection to the emissions control system

In modern trucks, exhaust pipes are not just simple pipes, but precisely manufactured components that are integrated into the complex emissions system. The pipes are directly connected to the particulate filter (DPF) and the SCR catalytic converter. The absolute tightness of these connections is crucial: leaks would lead to the release of unfiltered exhaust gases and interfere with the sensors (pressure, temperature, NOx) in the system, which can lead to error messages and a reduction in engine performance (emergency running program). The precise fit of each pipe flange and the quality of the retaining clamps are therefore essential for the correct functioning of the entire Euro standard system.

Economic efficiency through remanufacturing and material selection

Due to the high costs associated with replacing solid exhaust pipes and the sustainability aspect, the use of remanufactured exhaust components is also becoming increasingly important in the truck sector. Regardless of whether it is a new or remanufactured part, the longevity of the exhaust system depends on the choice of material. Stainless steel or highly aluminized steel offers the necessary resistance to external corrosion caused by road salt and moisture as well as internal corrosion caused by exhaust gas condensates. Investing in tested, heat-resistant components minimizes the risk of unscheduled workshop visits and ensures the cost-effectiveness of the truck fleet.